Commitment to Quality

Quality

As a privately run company we are able to react to market and production changes and invest in new machinery where required to remain competitive on quality, price and delivery. We have operated to recognised quality standards for more than 30 years and are certified to BS EN ISO9001.

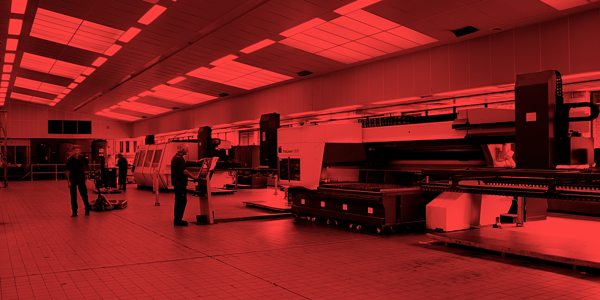

Today, our 78,000 sq ft plant handles between 800 and 1000 jobs each month in a clean, temperature-controlled environment conducive to high quality work.

Our loyal, skilled workforce has substantial experience in all aspects of manufacturing, planning and carrying out work of the highest quality.

History

We have come a long way since our humble beginnings in 1966 when our current MD started all those years ago in his then business partner’s spare bedroom. An experienced machinist, he saw an opportunity for a reliable and flexible subcontract manufacturer who could deliver exceptional quality.

To this day we are still as excited and interested in engineering as he ever was and the company still upholds the same principles of outstanding Service, Quality & Delivery that were set all those years ago.

Our People

As a family run business, we have many long-serving employees and a low turnover of staff. With a stable, skilled workforce we can be confident in the quality of workmanship and commitment to delivery that is valued by our customers. Multiple skills and a flexible approach ensure smooth introduction of new techniques and efficient handling of new projects.

Our staff are frequently involved in improving production efficiency and seeking ways to remove cost from our processes. Consultation on the selection of new plant and thorough training ensure that we make the most from new investments.

Processes

Estimating, scheduling and production control

Controlled by our bespoke software

Realtime reporting

Efficient QC feedback loop

Design & Programming

We can receive drawings and files in all industry standard formats. From your drawings, we will program production machinery off-line using Solidworks, Computes and Trutops software.

With extensive experience of precision sheet metal production, we can advise on optimum production methods to reduce lead times and improve quality.

All industry file formats

Extensive experience

Optimum production methods

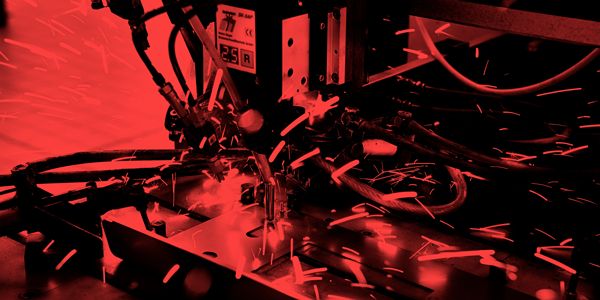

CNC Laser & Punch

With automated laser cutting and punching we can ensure efficient 24/7 production of short runs or volume production. Our Trumpf lasers have a working range up to 3000 x 1500 mm, delivering even complex shapes ready for use without further deburring.

Three Amada presses provide high volume CNC punching capability with sheet loader, part picker and tower storage.

24/7 production

3000 x 1500mm capacity

High volume punching

Fabrication

CNC folding, stud welding, bushing, MIG - TIG and gas welding, deburring and graining.

Seven brake presses provide high levels of accuracy in precision bending and forming for a wide range of materials. CNC control minimises handling and cycle times to give high quality and short lead times. Auto-fed stud welding and bushing machines can be set up quickly to give cost effective and highly accurate performance. MIG, TIG and Gas welding are carried out to commercial standards. Full graining, deburring and cleaning facilities are available.

CNC Folding

Stud welding & bushing

Precision welding

CNC Milling

To complement our sheet metal services we offer sub-contract CNC milling services under one roof. By offering our customers a reliable and efficient precision CNC machining service we provide assurance that we can manage all aspects of their project or products under an all encompassing accredited quality umbrella.

Our range of CNC Machines and trusted sub-contract CNC Machinists enable us to offer comprehensive and dedicated service to our customers.

Subcontract CNC Machining

Accredited quality umberella

Comprehensive, dedicated service

Finishing

Powder coating, wet spray painting, silk screen printing.

Finishing operations are all carried out in our factory, eliminating the time and cost of transferring components. Electrostatic powder coating uses a conveyorised line for maximum efficiency and consistency. Two conventional wet spray booths are used for stoving enamels and acrylics. Four silk screening benches cover print areas up to 1450 x 900 mm.

Powder coating

Wet spray painting

Silk screen printing

Assembly & Dispatch

Component assembly, riveting, packaging, call-off and dispatch from our dedicated clean area, undertaking riveting and assembly of manufactured and supplied components. we make complete subassemblies ready for your production.

With guaranteed quality standards, we are regularly trusted to ship straight to production lines. Complete items can also be supplied ready for dispatch, packed in paper, foam, boxes or bespoke systems as required and delivered by our own transport.

Production ready component assembly

Component call-off

Direct shipping to your production lines

Contact us

For quotations, enquiries and to book a tour of our facility, call our technical team on 01280 829200 to discuss your project.

We look forward to meeting you